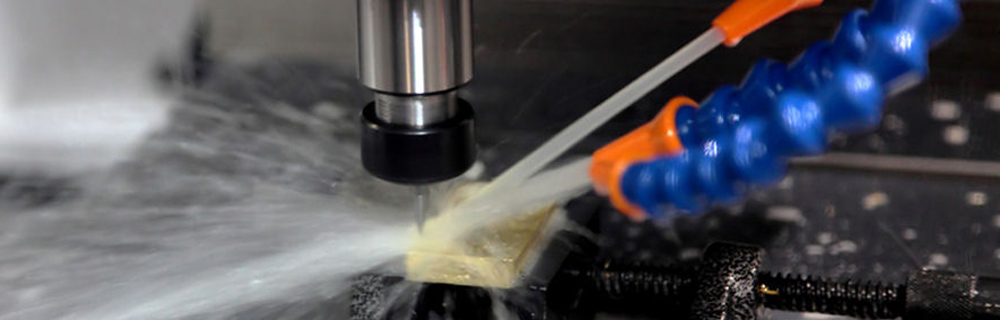

Waterjet Cutting Methodology

Backed by a dexterous team of expert service professionals, we offer Waterjet Cutting Methodology Service. Our professionals follow a waterjet cutting methodology process for accurately and precisely cutting the hard metals and non metals. This process is easy to control and is highly advanced programmable system, which helps in offering better handling and innovative cutting solutions.

Working methodology:

- In the waterjet cutting methodology water is passed at a high pressure of 55000 psi and at a high speed of 900 m/s through a tiny orifice.

- After passing water at a high speed and high pressure, coherent extremely high and thin velocity waterjet is produced that has a diameter ranging from 0.08 to 0.50 mm.

- Through this process the natural garnet sand particles are sucked into the stream of the coherent waterjet.

- Sand particles and natural garnet are precisely directed to hit the work piece part on the required cutting line with extremely high velocity force.

Waterjet Methodology

We are one of the trusted service providers, engaged in providing Waterjet Cutting Methodology Service. Waterjet cutting methodology is a process of micro erosion, which is used for accurately cutting hard metals and non metals. This process is easy to control and is highly advanced programmable system used for innovative cutting solutions and better handling of metals and non metals.

Working methodology:

- The process involves passing of high-pressure water at 55000 psi through a tiny orifice at a very high speed of approx. 900 m/s – which is equivalent to three times the speed of sound.

- As a result it produces a coherent extremely thin and high velocity waterjet, with a diameter ranging from 0.08 to 0.50 mm.

- Through this process the natural garnet sand particles are sucked into the stream of the coherent waterjet.

- The sand particles and natural garnet are precisely directed to hit the work piece part on the required cutting line with extremely high velocity force.